Building an aluminum alloy warehouse tent requires systematic planning, professional installation, and quality control. Below is a detailed step-by-step guide to help you smoothly complete the entire process from design to commissioning.

Preliminary Planning and Preparation

Clarify Requirements and Site Survey

First, determine the warehouse tent’s purpose (e.g., raw material storage, cargo transit), required capacity (volume of cargo, need for reserved aisles), and service life (temporary storage or long-term use). Then, conduct a comprehensive site survey:

- Measure the site dimensions to confirm available space and avoid surrounding obstacles (e.g., trees, utility poles) that could hinder construction.

- Check the ground conditions. Different surfaces, such as concrete, asphalt, and grass, require different fixing methods (e.g., expansion screws, ground nails, ballast blocks, etc.).

- Understand local climate conditions, such as maximum wind speed, rainfall, and snow depth. These will affect the tent’s wind resistance rating, drainage design, and other parameters.

Design Plan

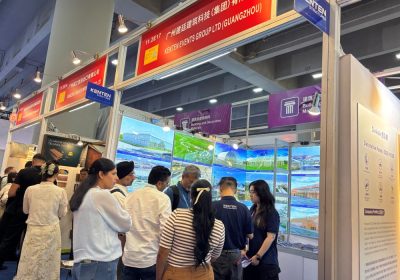

- Contact the KENTEN aluminum alloy tent manufacturer for a design based on your needs and site data, including:

- Tent dimensions: span (typically 10-60 meters), length (extendable as needed), and side height (to prevent forklifts and other equipment from entering and exiting).

- Structural configuration: whether side walls are required (enclosed, open, or removable), door and window locations, ventilation system, lighting layout, etc.

- Material Selection: The frame should be constructed of high-strength aluminum alloy (such as 6061-T6), and the tarpaulin should be made of abrasion-resistant, waterproof, and UV-resistant PVC.

Material and Equipment Preparation

Core Material Procurement

- Aluminum alloy frame: This includes the main frame, columns, and connectors. Ensure the material meets national standards and has sufficient load-bearing and wind-resistant capabilities.

- Tarpaulin: Select a PVC tarpaulin of appropriate thickness based on the intended use. If insulation is required, sandwich panels or a tarpaulin with a thermal insulation layer can be used.

- Accessories: Sealing strips (to prevent leaks), fixings (expansion bolts, ground spikes, iron weights), gutters, doors and windows (rolling doors, sliding doors), etc.

Construction Steps

Site Cleaning and Foundation Preparation

- Clear the site of debris and rocks, and level the ground. If the ground is uneven, level it (e.g., by laying gravel or concrete pad).

- Mark the tent installation location according to the design plan, determine the position of the columns and gutters, and ensure accurate subsequent construction.

Frame Assembly and Fixing

- Bottom Structure Installation: First, lay the bottom load-bearing beams and secure them with connectors, ensuring that all components are aligned and level. This is the foundation for overall structural stability.

- Column and Main Frame Assembly: Vertically secure the columns to the bottom load-bearing beams, using a level to calibrate verticality. Then, install the main frame (crossbeams and longitudinal beams) and connect them to the columns with bolts to form the overall framework. 3. Reinforcement and Wind Resistance: Install diagonal braces and scissor braces to enhance the frame’s wind resistance. Secure the base structure according to the surface type. For example, anchor concrete surfaces with expansion bolts, secure grass surfaces with extended ground spikes, and add weights for soft surfaces.

Quality Inspection and Post-Maintenance

Acceptance Inspection

- Structural Stability: Check the frame connections for security and verticality. Perform a shake test to confirm wind resistance.

- Sealing: Use a water hose to simulate rainfall and inspect the tarpaulin seams, doors, and windows for leaks.

- Functional Integrity: Test the doors, windows, lighting, ventilation, and other features for proper operation.

Daily Maintenance and Care

- Regular Inspection: Check the frame connections for looseness and the tarpaulin for damage or deterioration monthly. Tighten or replace them promptly.

- Cleaning and Maintenance: Wash the tarpaulin at least annually (using a neutral detergent) to prevent oil and debris accumulation that may affect its service life.

- Seasonal Protection: Clear snow in winter to prevent excessive weight from collapsing the structure. In summer, check the drainage system for proper operation.