Why Aluminum Alloy May Be the Future of Construction

When considering the materials for construction projects, the choice between steel and aluminum alloy is crucial, especially in terms of cost. Steel has traditionally been the go-to material due to its lower initial cost, but aluminum alloy is emerging as a more cost-effective and sustainable option in the long run. This article will explore the cost implications of using steel versus aluminum alloy and discuss why aluminum alloy might be the future of construction.

1. Initial Costs: Steel vs. Aluminum Alloy

Steel is widely recognized for its lower initial cost compared to aluminum alloy. This makes steel a more attractive option for projects with budget constraints. According to reference , steel construction generally has a lower upfront cost, which aligns with its widespread use in construction projects where initial expenses are a primary concern.

However, it’s essential to look beyond the initial costs and consider the long-term financial implications. While steel may be cheaper at the start, its maintenance and upkeep can significantly increase overall expenses over time.

2. Long-Term Costs: Aluminum Alloy as a Cost-Effective Option

Aluminum alloy, though more expensive initially, offers substantial long-term cost savings. Reference highlights that aluminum constructions require less maintenance and are more cost-effective over time. This is particularly beneficial for long-term projects where the cumulative maintenance costs of steel could outweigh the initial savings.

Moreover, aluminum’s integral finish eliminates the need for frequent refinishing, which is a common requirement for steel structures to protect against corrosion. This reduction in maintenance needs not only saves money but also extends the lifespan of the structure.

3. Durability and Corrosion Resistance

Aluminum alloy is inherently more resistant to corrosion compared to steel, reducing the need for additional protective coatings. This natural resistance not only lowers maintenance costs but also enhances the durability of aluminum structures, making them a reliable choice for various environmental conditions.

4. Sustainability and Environmental Impact

In an era where environmental sustainability is a significant concern, aluminum alloy stands out as a more eco-friendly option. According to reference , aluminum is 100% recyclable and can be reused repeatedly without losing its properties. This makes aluminum construction a more sustainable choice, aligning with global efforts to reduce the environmental impact of construction projects.

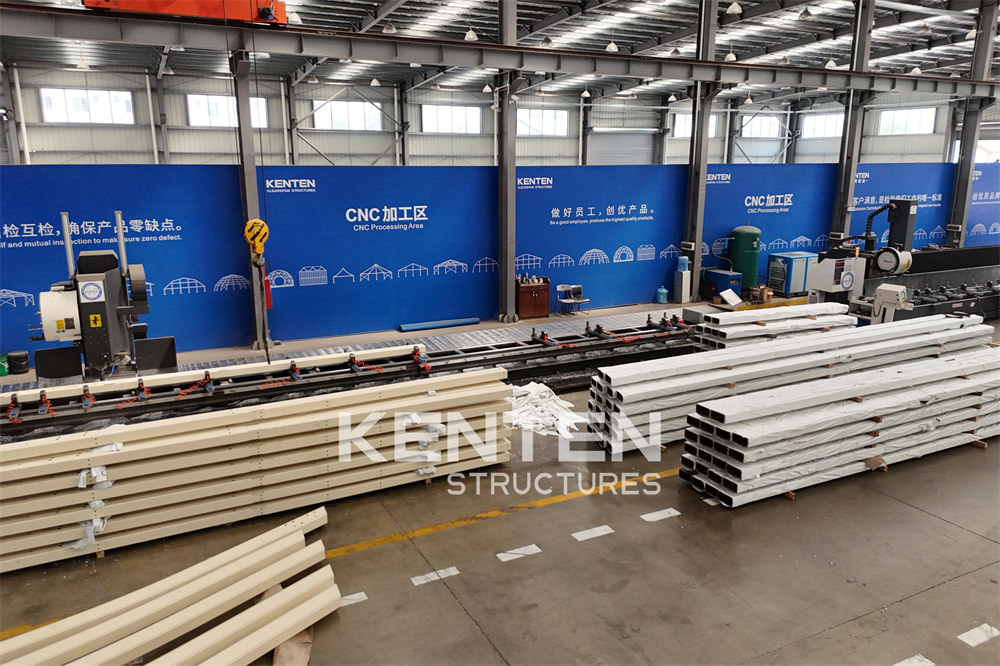

5. Strength and Versatility

Despite its lower weight, aluminum alloy offers a commendable strength-to-weight ratio, making it a competitive alternative to steel. This versatility allows architects and engineers to design structures that are both strong and lightweight, opening up new possibilities in construction.

Conclusion

While steel remains a cost-effective option with lower initial costs, aluminum alloy emerges as the more economical and sustainable choice in the long run. Its reduced maintenance needs, durability, corrosion resistance, and environmental benefits position aluminum alloy as a preferable material for future construction projects. As the construction industry continues to evolve, aluminum alloy is likely to become the material of choice for those seeking a balance between cost-effectiveness, durability, and sustainability.